Current market trends require an expedited and validated product for time to market and cost competitive environment. The market users need innovative yet better substitutes of the existing products or even superior products. These market trends encourage the low cost and fast designing, prototyping, testing, and design validation within lowest most times.

One who is the time winner to launch a product much comparable to its competitors has held over the market. These have been reduced by introducing the state of the art 3D printing technology for product designers and developers. Although 3D printing is not very new to usage, it was introduced and tested in the eighties. A boom occurred in its remarkable services and utilization in last two decades.

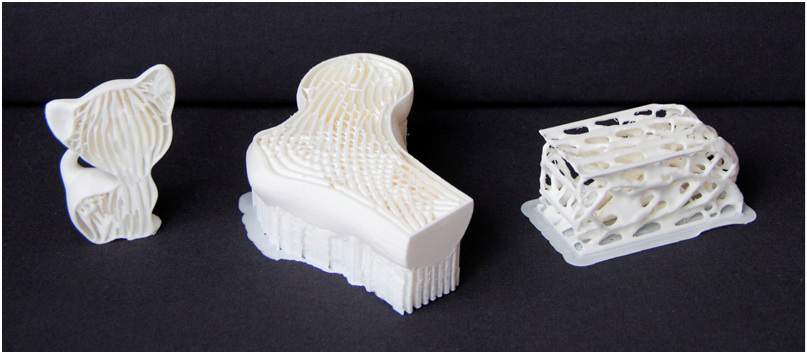

The terms 3D printing-cum-manufacturing, additive manufacturing and rapid prototyping almost refer to the same type of operation. Actually, in more accurate terms, the rapid prototyping is the utilization of additive manufacturing for manufacturing of mechanical parts by using 3D printing technique. This is a time saving and cost saving solution for prototype development.

In additive manufacturing, for instance, to manufacture a plastic part of a car, it is considered an effective method of fast and rapid prototyping i.e., a 3D printer is used to form the part by joining small slices of material so it finds an exact shape of the part.

It is much different relative to the CNC machining in which a block of a large metal piece is eroded to create a hole or give it shape according to the requirements.It is the process of parts building by joining sliced-material layer on layer.

The design is modelled in CAD (Computer Aided Design) software. After a CAD sketch is modelled in software, the additive manufacturing equipment i.e., 3D printer interface with computer software reads the data from the CAD file and adds successive layers of metal, ceramics, powder, molten metal, in a layer-on-layer fashion to fabricate a final 3D object.

There is no end to rapid prototyping consumption and applications. The rapid prototyping technology through additive manufacturing is used for highly sophisticated and specialized military equipment, airborne systems and aircraft, dental restorations, medical implantations, fashion products such as masks, in universities for research and teaching purposes, and automobile industry etc.

The moldchina.com (https://www.moldchina.com/ ) is a leading manufacturer of plastics moulds and plastic products based in China. It is a major source of supply for standard products for Europe and Western countries. For plastics manufacturing as for other engineering products, it is a tendency to introduce better quality products in the smallest cost and shortest possible time. The market trend is to introduce and launch innovative and to complete specific requirements of end users. It is changing even the marketing strategies of companies.

The plastic injection moulding process is the widely used method in fast and rugged prototype development techniques. This process includes the very fine granules of plastic material to be heated using heating bands along with the rubbing action of back and forth moving screw barrel. It is then melted and injected under pressure to full a mould. This process is very fast and copy paste the products in an exact manner

The highly considerable norms for successful product manufacturing and market capture are:

The rapid prototyping helps to keep the main focus on purpose specific to product creation. The industry is moving from mass production to environment production due to its more profitable return. The rapid prototyping using additive manufacturing by 3Dprinting is friendlier for environment production. It has reduced the overall time for product launch considerably. Due to short time low cost of development, it has reduced overall product price. The rapid prototyping is more environmentally friendly that makes it easy compliant for different environmental safety standards.

It is a quite game-changing technology in mechanical manufacturing. For a successful part built it needs three main steps:

Creation of three-dimensional part model using any supported software such as SolidWorks, AutoCAD, Catia and/ or Pro-E etc.

Creation of supported manufacturing file such as *.stl which is used for rapid prototyping by using 3D printers, cutting the mechanical parts into slices and creation of physical layers.

Joining the layers with each other to form the final part.Removing the residuals for the final part to make it a finished part.

Although, the applications of 3D based additive manufacturing technology is still in infancy for end-user parts manufacturing the potential benefits are enormous. It allows for smaller equipment manufacturers to make their products rapidly setups to enter and launch to the market rather than conventional expensive and time taking methods.

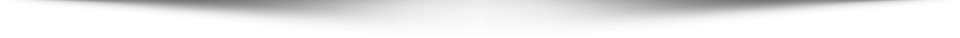

It offers the ability to produce parts which were not possible by using traditional processes and techniques. Some of these parts are like complex internal channels, lattices etc. This technique is very useful from aerospace to automobile products, and the parts which require complex manufacturing processes and customization, for their prototyping from low to high volume production.

The in-house making of mould will significantly lower the prices for parts manufacturing due to economical labour and cost-effective raw material. The 3D Additive Manufacturing (AM) will allow production of parts on-demand basis without dedicated tools.

The project manager of the part manufacturing industry should be the one who coordinates and manages the entire process by his own abilities thus reducing the requirement of additional staff hence cutting the cost of producing parts